Failure of electrical equipment can be a costly mistake for any business which relies on large machinery. Many brands will spend tens to hundreds of thousands on electric repairs when any machine in their space fails. Alongside the high cost of operations, these companies may even be forced to spend time out of operation until repairs are fully carried out.

Electrical mishaps will affect different aspects of your operation for a significant set-back. Brands need to put in more effort to prevent any likely occurrences which may affect their output. The best way to prevent these potentially costly errors is to regularly maintain your equipment and take better care when in use. This article offers valuable tips to help you improve your equipment’s critical maintenance for a lower risk of failure.

Table of Contents

Clean your systems

The first step to protecting your electrical equipment is keeping it as clean as possible. You need to take better care to avoid damage and fire for your electrical equipment. This translates to tackling dirt build up at least once a day when the machine is in use. You should clean your machine and leave it in a clean and dry place. This means avoiding any use of the machine as a storage space and scheduling regular cleaning efforts. In addition to these efforts, you should make sure that vents remain unblocked and all connections be fixed securely. This will prevent increased dirt build up rates that could raise the risk for electric failures. Avoid opening up any machines during your clean up procedure if you cannot comfortably restore them to efficient operations.

Contain the heat

You need to prevent any machine overheating to lower your risk of electrical mishaps. Even though it is commonly overlooked as a cause for electric mishaps, overheating can significantly hinder productivity. It can be contained by better machine management and use. This means regularly replacing filters, keeping cooling vents unblocked and maintaining all blowers and fans within a machine. You should consider regular assessment and maintenance of equipment with cooling components to protect against the knock-on effect of electrical failure.

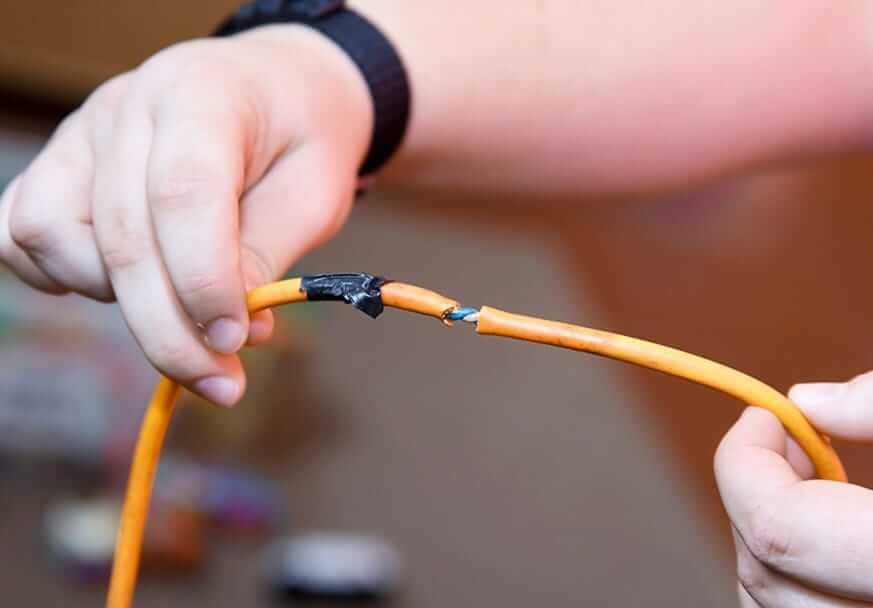

Tighten any loose connections

Is your machine well set up and connected to your system? Loose parts and connections will cause up to a third of all electrical equipment failure. You need to regularly assess your equipment to ensure secure connections and parts. This translates to addressing any weak wired connections, loosened bolts and inefficiently set up components. If you are doing it yourself, remember to consult the machine’s set up instruction and guideline for optimal set up.

Understand your equipment

If you do not have regularly scheduled maintenance, you may have to learn how to read the early signs for potential electrical problems. If you experience shocks when plugging in your equipment or hear a buzzing sound, your electrical system might already be compromised. Understanding your equipment can help you detect any early warning signs to prevent electrical failures before they occur. We recommend carrying out pre-shift inspections of your machines before setting out to use them to identify any mishaps early. You should also consider keeping your equipment turned off when no longer in use. You should consider hiring a technician to assess and maintain your equipment if you are not comfortable enough to look into it yourself. You can also set up guidelines for assessment to lower the risk of failure of equipment for any employees.

Why did your equipment fail?

Optimized maintenance will require some assessment of your equipment and system. You need to understand why your electrical equipment may have failed to better assess your risk in future. By figuring out what caused the problem, you will better prevent any future occurrences as well as contain current failure.

Most electrical equipment will fail as a result of collisions with other items, loosened parts and weak connections, increased exposure to moisture and short circuiting. Equipment may also fail as a result of lodged foreign objects, overloaded power lines, dirt accumulation and disturbances to power lines.

Even though most of these causes can be shielded against, it may be prudent to consider investing in top notch maintenance to minimize any risks faced. Remember to combine insight from experts at nriparts.com and your local technician to help curb the risk of electrical equipment failure.