Power plant consultants and power plant engineering services play an essential role if you are launching a new project or improving existing operations. In this article, we will discuss cost-quality balance, industry experience, communication abilities, client feedback, reviews, and certifications of power plant engineering consultants in detail.

Table of Contents

What do Power Plant Consultants do?

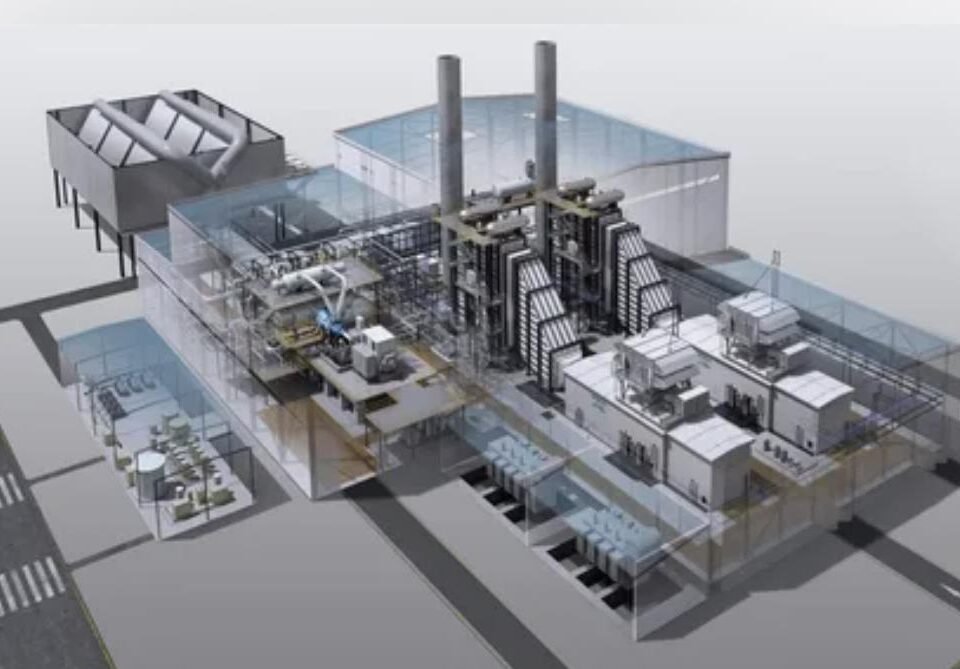

Throughout the energy sector, power plant consulting services play an important part in completely understanding complex power plant projects. They determine if projects are feasible and profitable through in-depth feasibility assessments, site selection, and financial modeling. They use cutting-edge software and analytical tools to provide optimized, exact plans for the plant’s mechanical, electrical, and structural components during the design and engineering phase. Consultants oversee projects from the initial design to final commissioning, assuring adherence to strict budgets, schedules, and regulatory constraints. They also play an integral part in the procurement process, where they carefully draft tender documents, assess bids, and skillfully negotiate contracts with vendors and contractors to make the project execution proceed more smoothly.

Balancing the costs and quality in Power plant projects- What steps to take?

Building a power plant requires enormous costs and labor. Therefore, thinking in advance and defining the project in proper detail is crucial to avoid extra costs and delays. In this section, we will discuss the steps required to maintain a balance between costs and quality in power plant consulting services and construction:

Define the scope of the project

Establishing precise goals and parameters for your plant engineering project is the initial stage in balancing quality and cost. What are the project’s functional and technical needs, performance standards, regulatory and environmental restrictions, and desired outcomes? At this point, it will be useful for you to think about implementing smart grids, which you can learn more about in this article. Setting clear and attainable goals and scope can help you stay away from issues like scope creep, change orders, rework, and delays that can make your project more expensive and less effective.

Plan the project

A well-planned and managed plant engineering project is the second stage in achieving a cost-quality balance. Your project’s tasks, milestones, deliverables, resources, budget, and timeline should all be carefully set out in a well-developed project plan. As a project manager, you must consistently monitor the status, performance, risks, difficulties, and modifications. You can stay on track with the project’s scope and objectives, use your resources well, finish it on schedule, and keep costs down with proper planning and management.

Choosing the right tools and methods

Choosing the appropriate methods and tools for your plant engineering project is the third stage in achieving a balance between cost and quality. Picking the right tools and procedures for design, analysis, modeling, testing, fabrication, installation, and commissioning is essential for achieving project goals in terms of quality and budget. You should also evaluate the integration, compatibility, and interoperability of the processes and tools you will utilize. Selecting the right methods and tools can enhance your plant engineering project’s accuracy, dependability, and safety.

Implementing quality control and assurance

Implementing quality assurance and control techniques throughout your plant engineering project is the fourth stage to balance cost and quality. If you want your project to meet the expectations and requirements, the firm needs to set and adhere to quality standards, processes, policies, and guidelines. The quality of your project’s outputs should be confirmed and validated by quality audits, inspections, reviews, and testing.

You can keep your project on track regarding quality and budget by utilizing quality assurance and control measures to identify and fix mistakes, flaws, and failures as soon as they happen.

Communication and Collaboration

Maintaining a healthy cost-benefit ratio in plant engineering requires constant two-way communication and close cooperation among all parties engaged in the project. This includes project managers, clients, stakeholders, suppliers, and contractors. To accomplish the project’s goals and objectives, the firm must be able to settle disputes, reach agreements, and plan actions. Everyone involved in a project can benefit from increased trust if they speak up and work together.

Power plant consultants- What to look for when selecting the consultants

Choosing the right power plant consultancy is critical for a power plant project. This requires careful consideration of many factors. These factors determine the quality and cost of your power plant project. Let us discuss these factors in detail:

Industry Experience

The level of expertise a power plant design company has is a key indicator of its level of excellence in this field. Think about hiring consultants with years of expertise in the power generation industry. If you want your project to be completed on time with no additional costs, you need a consultant who is well-versed in the industry and can help you navigate the unique obstacles, rules, and best practices.

Communication skills of the firm

Cooperation with consultants relies heavily on clear and concise communication. Select a firm specializing in communication, both in clarity and responsiveness. A consulting partnership can only succeed if both parties can communicate effectively, listen to each other’s issues and opinions, and work together to find solutions.

What current power companies are saying about the firm

Consulting with other power firms that have used the same firm in the past is a great way to get their review. Customer feedback and references can tell you a lot about a company’s dependability, performance, and standing in the market. You can understand the power plant consulting services’ strengths and weaknesses by speaking with people who have collaborated with them.

Reviews and Ratings

One easy and proper technique to evaluate a consulting firm is to look at their ratings and reviews online. Take note of the general satisfaction levels and the experiences prior customers provided. While reviews should not be the main determining factor, they can provide an overview of the firm’s prior performance and client satisfaction.

Certifications

Make sure that the consulting firm and consultants have the proper certifications. Certifications from renowned industry associations and organizations demonstrate a dedication to upholding industry standards and staying current on best practices. Additionally, these certificates can attest to their proficiency and skill in power plant projects.

Conclusion

Choosing reliable power plant consultants is the key to successful project completion. You can make an informed decision that fits with the goals and objectives of your project by considering factors such as industry experience, communication skills, feedback from current clients, internet reviews and ratings, and relevant credentials. A carefully chosen consulting firm can offer the necessary experience and direction on your power plant project, resulting in cost-effective and high-quality results.

Author:

Robert C. Green

The author is a metallurgy expert with a wealth of industry knowledge. With a passion for helping businesses optimize their processes and achieve excellence in metallurgical practices, they share valuable insights in their articles on metallurgy consulting.