In recent years, there has been a lot of talk about Industry 4.0. But what is it? Industry 4.0 is a term used to describe the fourth industrial revolution. A focus on data and technology characterizes this revolution, which profoundly impacts the manufacturing industry.

Hong Kong they are starting to see the effects of Industry 4.0. For example, factories are using more data to improve efficiency. And they are using technology to automate their processes. This is making manufacturing more efficient and cost-effective.

As Industry 4.0 HK continues to evolve, it will see even more changes in the manufacturing industry. For example, 3D printing is becoming more common. This technology can be used to create customized parts and products for each customer. This means that factories can produce products quicker and with less waste.

Table of Contents

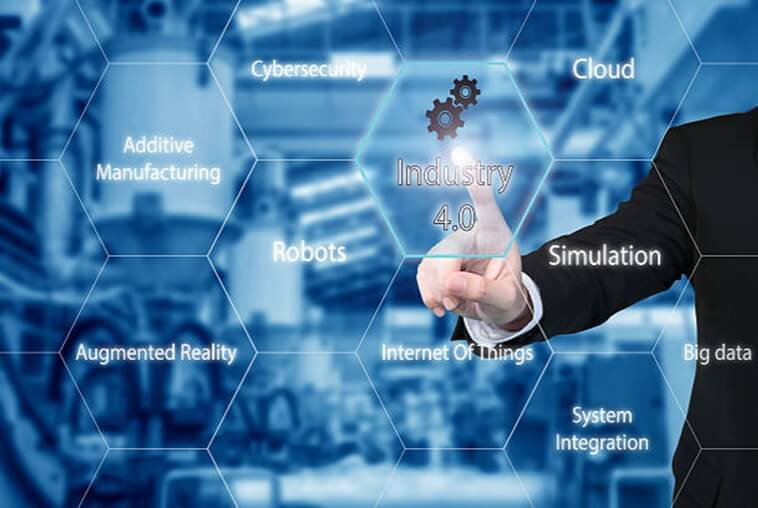

The Core Components of Industry 4.0

Technological advances in the digital age have given rise to Industry 4.0, the fourth industrial revolution. This industrial revolution is characterized by the integration of digital and physical technologies, which has led to the creation of the Internet of Things (IoT). Industry 4.0 has the potential to revolutionize manufacturing and the way we live. The core components of Industry 4.0 are:

Cyber-Physical Systems

One of the critical components of Industry 4.0 is cyber-physical systems. Cyber-physical systems are systems where physical and cyber systems are integrated and interact to share data and feedback. This type of system is essential for Industry 4.0 because it allows for the automation of production processes and data exchange between machines.

The Internet of Things

The IoT is one of the core components of Industry 4.0, as it allows manufacturers to collect data from their machines and use it to improve their processes.

There is already a wide range of IoT applications in the industry, from simple monitoring applications to more complex applications that use machine learning to optimize production. The IoT will majorly impact manufacturing in the coming years as more and more manufacturers adopt it to improve their operations.

The Internet of Services

The goal of Industry 4.0 is to create a more efficient, productive, and sustainable manufacturing sector. One of the core components of Industry 4.0 is the Internet of Services.

The Internet of Services connects people, devices, and services. This connection allows for the exchange of data and new services. The Internet of Services is a crucial component of Industry 4.0 because it creates new, efficient, and sustainable manufacturing processes.

Smart Factory

The smart factory is a core component of Industry 4.0, the fourth industrial revolution. Industry 4.0 is the integration of digital and physical technologies to create a more connected, agile, and responsive manufacturing system. The smart factory is a crucial enabler of this vision and is already becoming a reality in many manufacturing settings.

The smart factory leverages advances in connectivity, data analytics, and automation to enable a new level of visibility, control, and responsiveness in manufacturing. By connecting devices, people, and systems, the smart factory can collect and utilize data more effectively to optimize production and minimize downtime.