Having the correct instruments is vital for running a successful commercial kitchen. A commercial meat cutter is an essential piece of equipment for many restaurants and delis. This equipment can help you save time and money while guaranteeing that your meat is sliced consistently and precisely. But, with so many types and models on the market, deciding which one to buy can be difficult.

This article will discuss what you need to know when buying a commercial meat cutter and help you make an informed decision.

Table of Contents

Types of Commercial Meat Cutters:

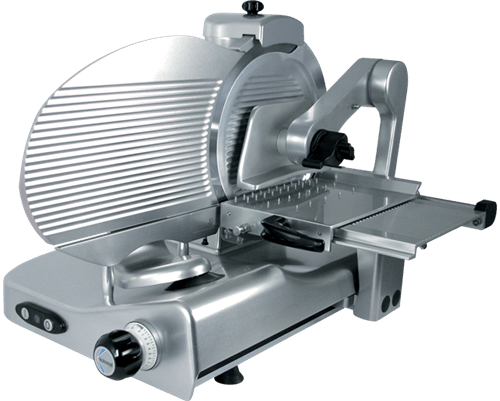

The first thing to consider when purchasing a commercial meat cutter is the type. Gravity-feed slicers, vertical slicers, and horizontal slicers are the three basic varieties.

Gravity-feed slicers: The most common sort of meat cutter is a gravity-feed slicer, which is ideal for cutting deli meats and cheeses. These devices are simple to use since they use gravity to feed the meat through the blade.

Vertical slicers: Vertical slicers are great for larger pieces of meat and can handle more food. These machines are commonly found in supermarkets and meat markets.

Horizontal slicers: Horizontal slicers are the most powerful meat cutters, capable of quickly cutting enormous amounts of meat. These machines are frequently seen in industrial settings.

What Features to look for:

When you’ve decided on the sort of commercial meat cutter you need, the following step is to consider the features you want. The following are some significant features to look for:

Blade Size: The blade size determines the greatest size of meat that you can cut. A bigger blade can cut through larger pieces of meat, but it is also more costly.

Blade Material: Carbon steel or stainless steel are the most common blade materials. Carbon steel blades are less durable than stainless steel blades and require less maintenance.

The sharpness of the blade: Cutting meat cleanly and effectively requires a sharp blade. Seek a machine with a sharp blade that can be readily sharpened or changed.

Safety features include: Meat cutters may be dangerous, so look for models with safety features such as a blade guard and an automatic shut-off.

How to Use a Commercial Meat Slicer:

Once you’ve purchased your professional meat cutter, it’s critical to understand how to use a commercial meat slicer properly to achieve the greatest results and avoid harm. Here are the actions to take:

- Prepare the Meat: Make sure the meat is at the proper temperature and firmness before using the meat slicer. It should be refrigerated but not frozen, and it should be hard enough to maintain its shape when cut.

- Adjust the Blade: Adjust the blade to the desired meat thickness. The blade on most machines can be adjusted using a dial or knob.

- Start the Machine: Start the machine and wait for the blade to get up to full speed.

- Feed the Meat: Put the meat on the carriage of the slicer and feed it slowly through the blade using the hand guard. To slice the meat uniformly, use a steady back-and-forth motion.

- Cleaning the Machine: After using the meat slicer, fully clean it to prevent bacteria growth. Remove the blade and wash it individually before wiping the machine down with a moist cloth.

Maintenance and Cleaning Tips for Commercial Meat Cutters:

Cleaning and maintenance are essential for keeping your industrial meat cutter in good operating order and preventing infection. A clean and well-maintained meat cutter makes sure that your meats are cut evenly and correctly and reduces the chance that bacteria will grow and make you sick.

It is critical to clean and sterilize your industrial meat cutter regularly to keep it in good working order. Then, unplug the machine and remove any easily removable elements, such as the blade, carriage, and slicer. Before reassembling, these pieces should be washed in warm, soapy water, rinsed, and well-dried.

Wipe off all surfaces on the main body of the machine with a moist cloth, giving special care to any areas that come into contact with food. Remove any food trash or oil buildup that can harbor bacteria.

Regular maintenance, besides cleaning, is required to keep your industrial meat cutter in good operating order. As part of the maintenance, any moving parts, like the blade drive and carriage assembly, need to be oiled and checked for wear or damage.

Sharpening the blade is another vital maintenance task. A dull blade not only produces poor-quality cuts but is also hazardous to use. Most meat cutters include an in-built sharpener or may be sharpened manually with a sharpening stone. It is critical to follow the manufacturer’s sharpening guidelines and to verify that the blade is properly aligned.

In conclusion, appropriate industrial meat cutter maintenance and cleaning are critical for preserving its longevity and preventing contamination. By following this advice and these instructions, you can keep your machine in good working order and regularly create high-quality pieces of meat.

Final Words:

Purchasing a commercial meat cutter can be an expensive investment for your company, but it can save you time and money in the long run. You may make an informed decision and achieve the greatest results by evaluating the sort of meat cutter you require, the features you require, and how to use it effectively. When using a meat slicer, always follow proper safety practices and keep it clean and well-maintained to prevent bacteria growth.